DriveBOT actuators for intelligent motion.

New generation of our DriveBOT servo actuators make almost any machine more compact, lighter and more powerful.

Servo actuator DriveBOT

Reduce system complexity and system costs

Servo actuator DriveBOT

Enable your engineers to work faster

Servo actuator DriveBOT

Make your machines leaner, greener & smaller

Servo actuator DriveBOT

All-in-one actuator from one source

Develop and deploy industrial machines faster, simpler and more efficiently.

Benefit from the combination of proprietary hardware and software

Construction Simplicity

Lower Instalation Dimensions

Easy to Use

Low Weight

Compact Modular Design

Low Cost Maintenance

Step by step to your own actuator

8 weeks from initial consultation to delivery

8 weeks from initial consultation to delivery

Initial Consultation

Once we receive your technical requirements, following will take a place:

- analysing your requirements

- discussing your specific needs

- preparing your actuator configuration

- providing all necessary data

- analysing your requirements

- discussing your specific needs

- preparing your actuator configuration

- providing all necessary data

Order & Production

In this step, please:

- check all provided data

- confirm your order

Now we will start production of all your servo actuator components

- check all provided data

- confirm your order

Now we will start production of all your servo actuator components

Assembly & Testing

Once all standard and specialized components are available, following activities will take a place:

- assembling your servo actuator

- product testing

- packing your order

- assembling your servo actuator

- product testing

- packing your order

Delivery

When your order is prepared, we will:

- doublecheck agreed delivery terms

- order the transport

- submit your order for shipment

- doublecheck agreed delivery terms

- order the transport

- submit your order for shipment

Support

Any questions?

We will be happy to support you in your further design and development process.

We will be happy to support you in your further design and development process.

Step 01

Step 02

Step 03

Step 04

Step 05

Application Possibilities

Configurable rotary actuators for more ambitious applications such as:

Rotary joints of robotic devices

Positioning modules of indexing tables

Electric wheels of mobile devices

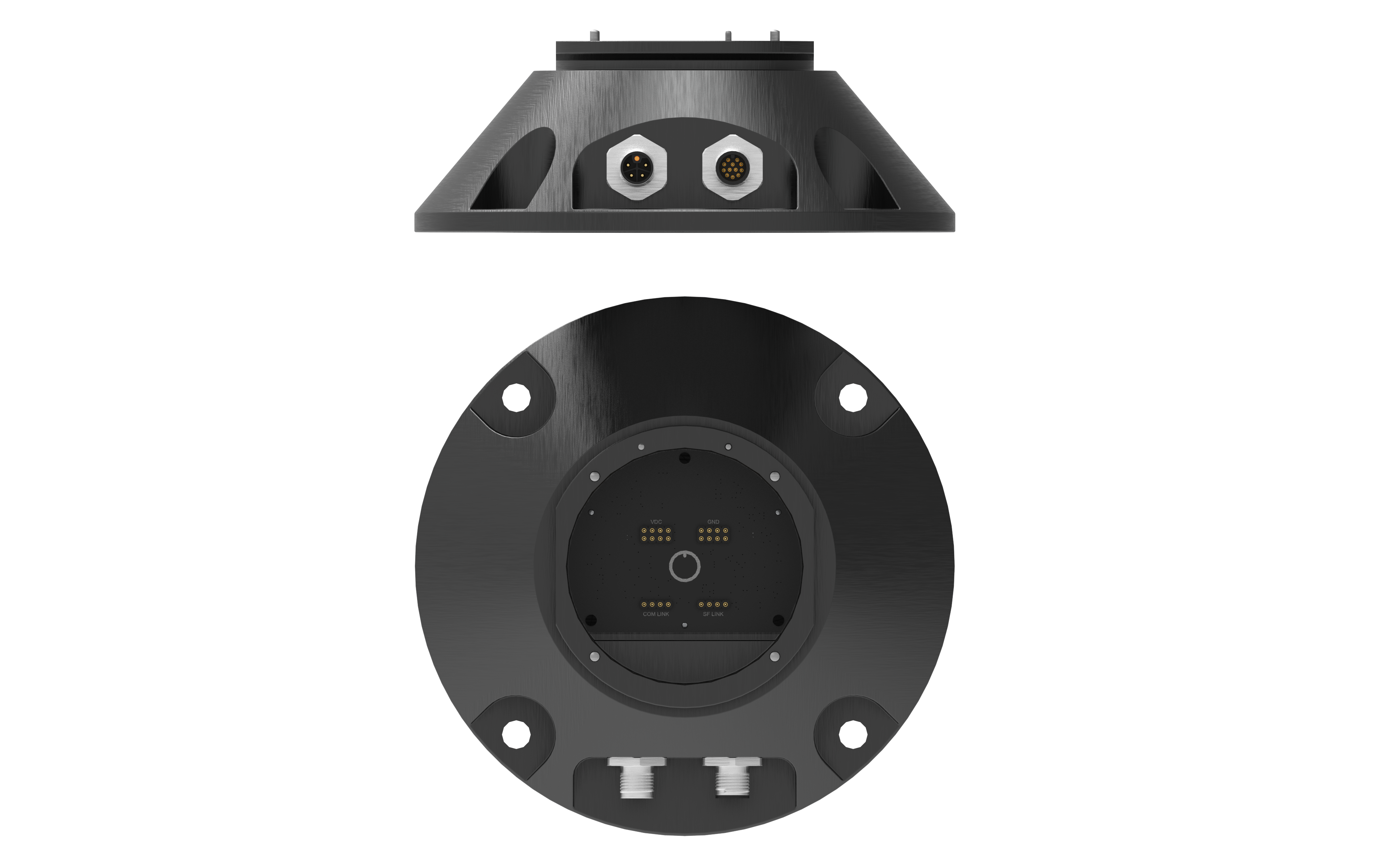

Core Modules

One Compact Unit - all essential elements

Control Module

Brake module

Drive Module

Connecting Module

Output Module

tab-6-block-8

The control and performance block of the DriveBOT that contains:

DriveBOT Controller (Standard or Safety Design available)

Input Power and Data Interfaces

Power and Data Distribution

RS485/MODBUS RTU, CAN Bus or MODBUS TCP Communication

DriveBOT actuator Safety Element that contains:

Electro-magnetic Safety Braking System

Drive block with actuator feedback system that contains:

Brushless DC Motor integrated into a Gear Block

Brushless DC Motor Position Sensor

Output Position Absolute Sensor

The transmission system for power and data distribution from static to rotary part of actuator that contains:

Power Transmission Block

Data Transmission Block

The covering element of the Connecting Module with output power and data interfaces for connecting to the next actuator or device that contains:

Power and Data output PCB

Power Output Interface

Data Output Interface

tab-6-description-block-8

tab-6-labela-block-8

tab-6-labelb-block-8

tab-6-labelc-block-8

tab-6-labeld-block-8

Servo actuator DriveBOT

Reduce system complexity and system costs

Servo actuator DriveBOT

Enable your engineers to work faster

Servo actuator DriveBOT

All-in-one actuator from one source

Servo actuator DriveBOT

Make your machines leaner, greener & smaller

Technical Possibilities

Design | Custom |

|---|---|

Included | Custom |

Core parameters:

Power | Custom |

|---|---|

Rated Voltage | Custom |

Rated Torque | Custom |

Speed | Custom |

Mass | Custom |

Absolute position sensor | Custom |

Power transmission system

| Custom |

Data transmission system | Custom |

Input interface | Custom |

Output interface | Custom |

Design | Solid |

|---|---|

Included | 3 core modules |

Core parameters:

Power | up to 470W |

|---|---|

Rated Voltage | 48V |

Rated Torque | from 12 Nm to 440 Nm |

Speed | from 13 rpm to 139 rpm |

Mass | from 1 kg to 10,24 kg |

Absolute position sensor | absolute encoder with multitturn counter |

Power transmission system

| No |

Data transmission system | No |

Input interface | RS485 / Modbus, CAN bus |

Output interface | No |

Design | Solid with transmission system |

|---|---|

Included | All 5 modules |

Core parameters:

Power | up to 470W |

|---|---|

Rated Voltage | 48V |

Rated Torque | from 12 Nm to 440 Nm |

Speed | from 13 rpm to 139 rpm |

Mass | from 1 kg to 10,84 kg |

Absolute position sensor | absolute encoder with multiturn counter |

Power transmission system

| max 30 A |

Data transmission system | max 8 x 1 A |

Input interface | RS485 / Modbus, CAN bus |

Output interface | CAN bus |